Model | Head 4 | Head 6 | Head 8 |

Output/ Hour* | 3600 to 6000 bottles. | 3600 to 9000 bottles. | 4000 to 12000 bottles. |

Direction of Movement | Left to Right | ||

Number of head/ Syringe | 4 Nos. | 6 Nos. | 8 Nos. |

Electrical Specifications** | |||

Main Motor | 1.5 HP/ 415 Volts/ 50 Hz. | 2 HP/ 415 Volts/ 50 Hz. | |

Cap Feeding Bowl | 2 HP/ 415 Volts/ 50 Hz. | ||

Height of Conveyor** | 860 mm to 910 mm Adjustable | ||

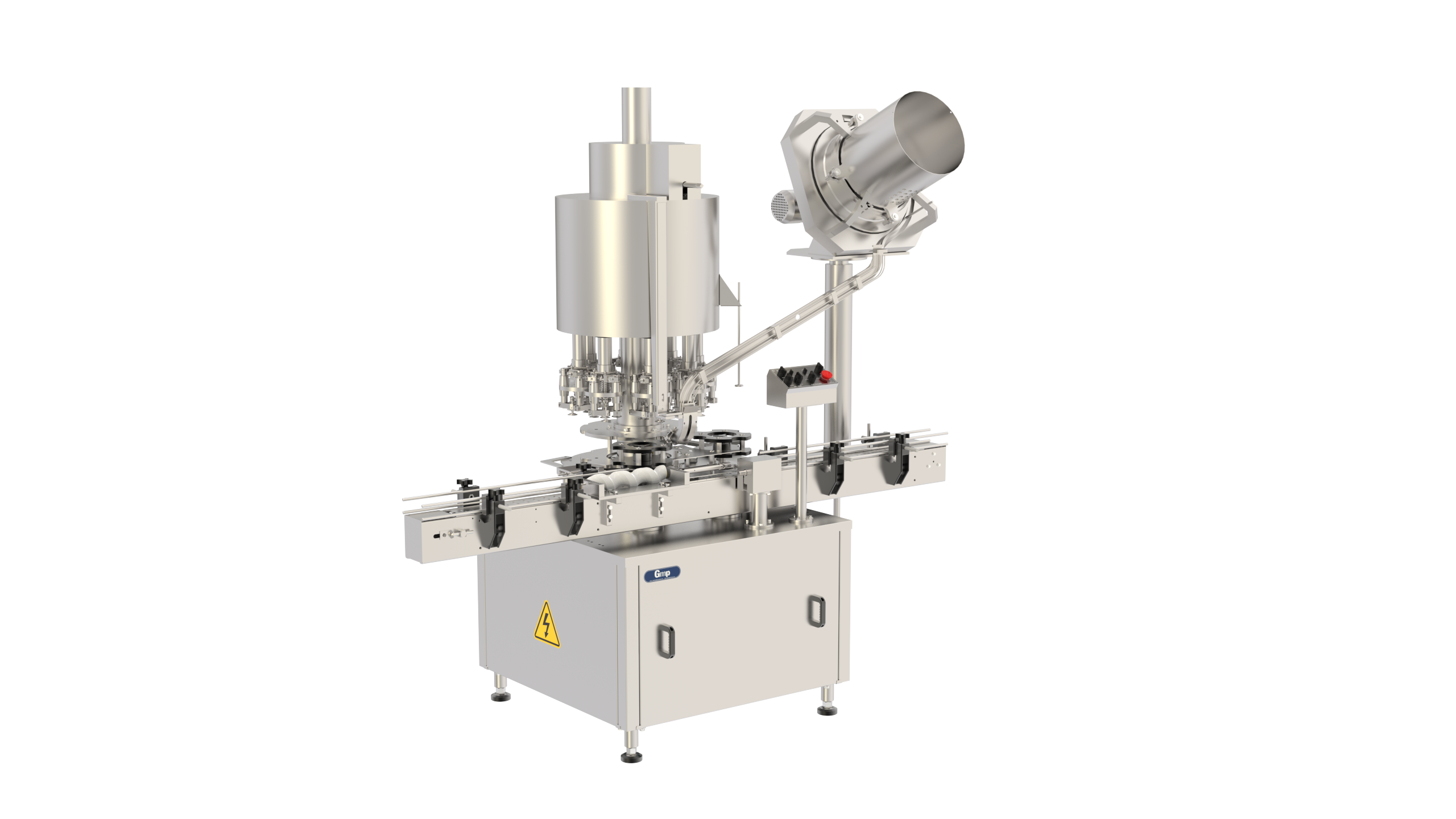

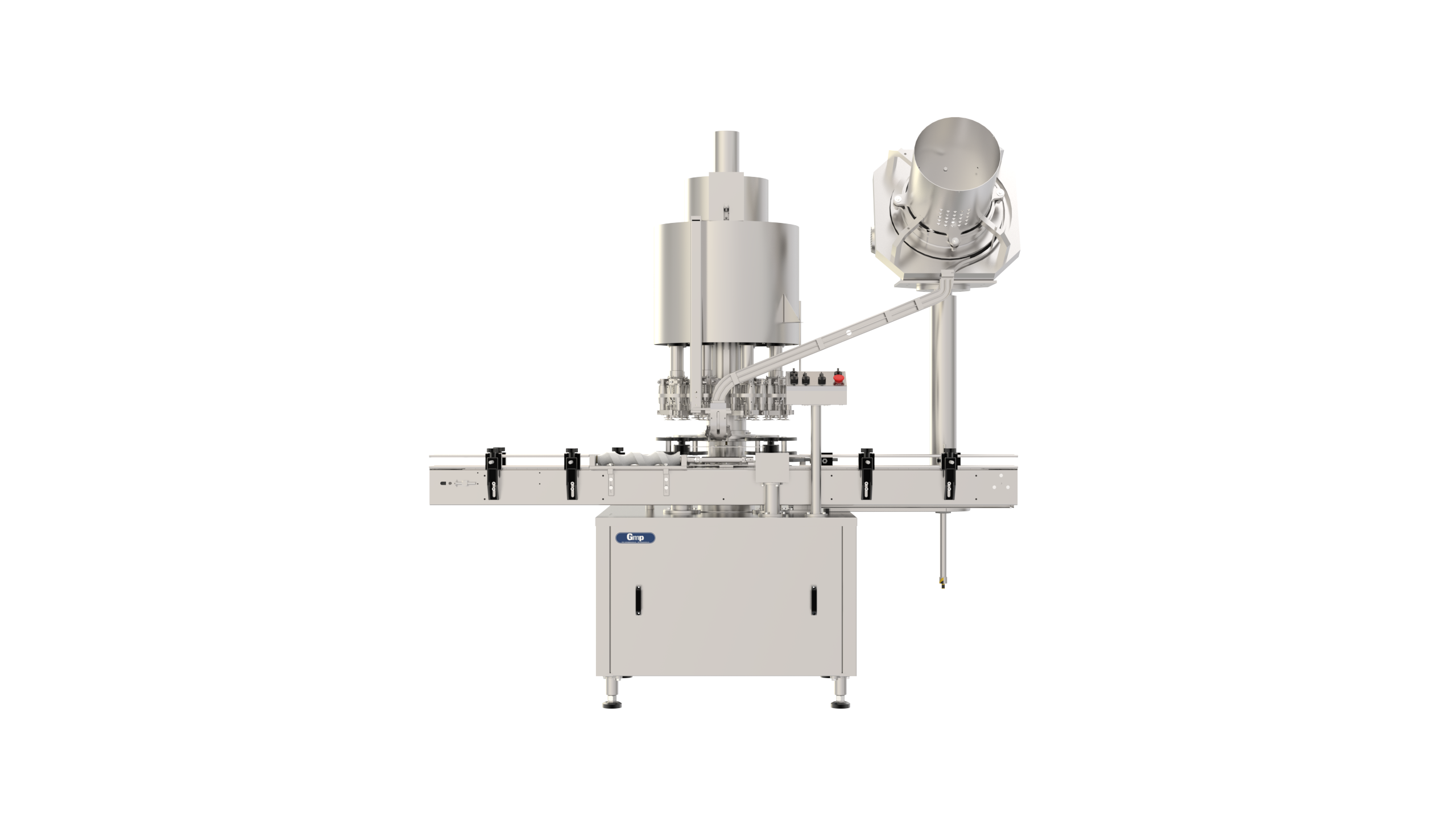

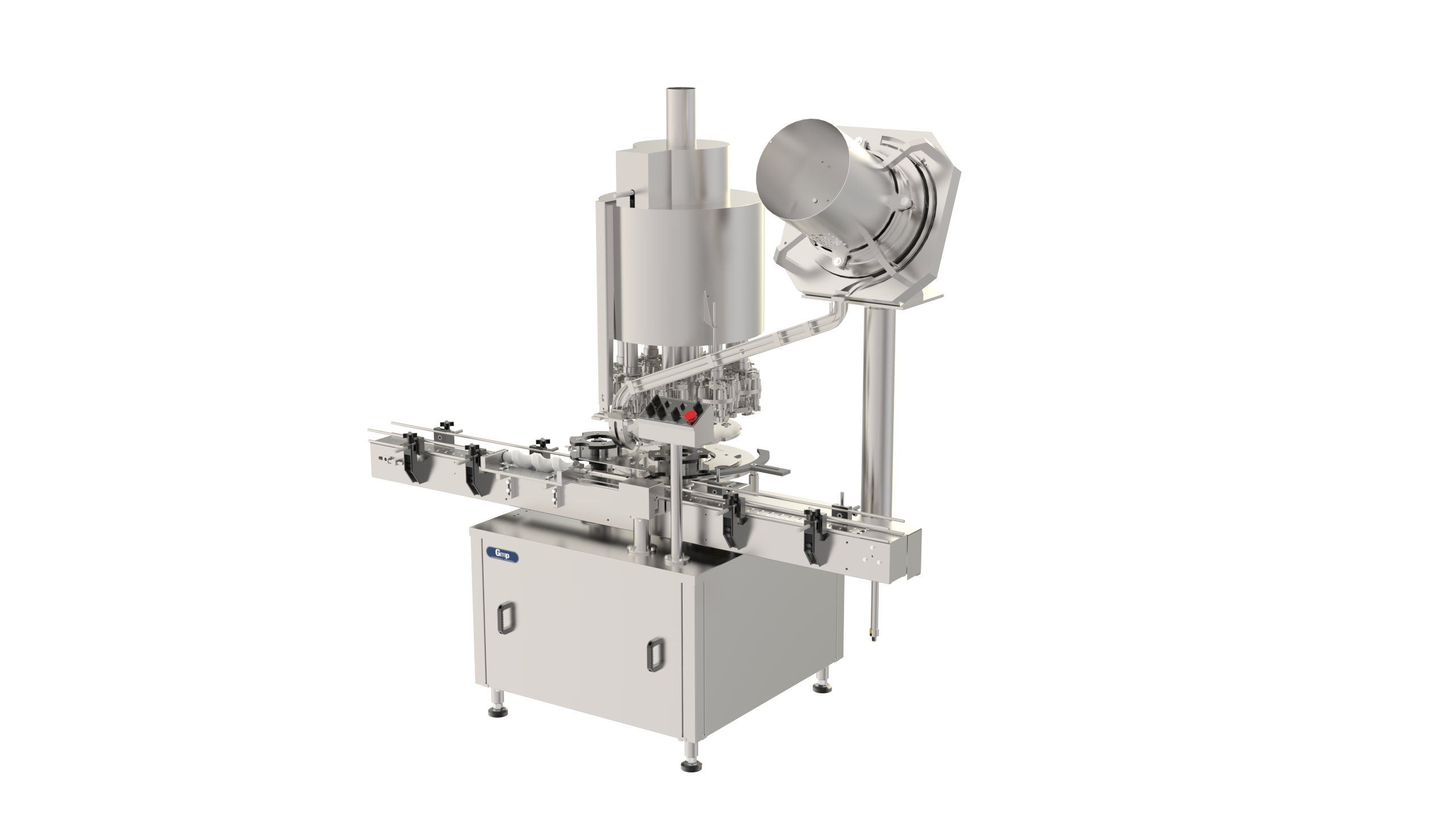

Automatic Multi Head Ropp Cap Sealing Machine

“GMP’s” Automatic ROPP Cap Sealing Machine is precision built on a sturdy welded steel frame completely enclosing in stainless steel sheet and doors are provided to facilitate the servicing of the machine.

Salient Features:

• No container no cap arrangement.

• S.S. elegantly matt finished body.

• Single motor synchronizes conveyor, star wheel, & platform turret.

• Adjustable height of conveyor belt, to align with other machines on the line.

• Sealing pressure can be varied to suit different gauges and sizes of caps.

• A specially designed hopper is provided to increase the storage capacity of the bowl.

• Low noise level, low power consumption.

• Self-lubricating UHMW- PE guide profile for low friction, smooth and noiseless conveying.

• Drain tray around the machine platform.

• SS cladding or hard chrome plating of all exposed parts to ensure a long life and resistance against corrosion.

• Synchronized A/C drives to synchronize conveyor, star wheel, platform turret & capping bowl.

• Universal coupling for quick and easy setting of In-feed worm.

• Adjustable bottle height gauge for easy and quick setting.

Reviews

There are no reviews yet.